Natural Gas Line: 3 Essential Steps for Safety

The Unseen Network Powering Your Home

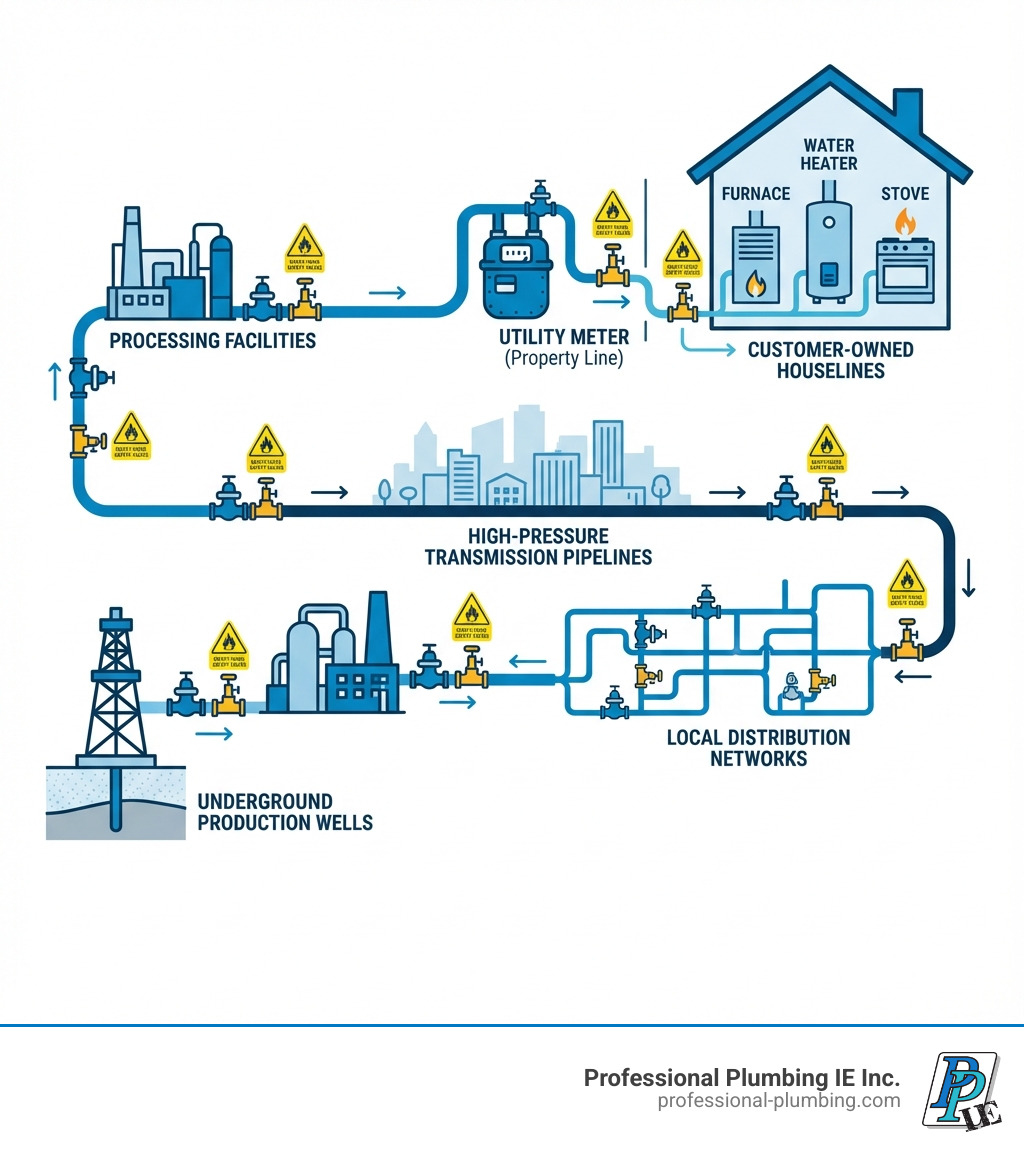

A natural gas line is the infrastructure that transports natural gas from utility mains to your home’s furnace, water heater, stove, and other appliances. This journey starts thousands of miles away at production wells, moves through processing plants, and travels via high-pressure transmission pipelines before entering smaller distribution lines in your community. Finally, a service line connects the main to your gas meter.

This vast system includes about 3 million miles of pipelines in the U.S., delivering roughly 29.2 trillion cubic feet of gas to over 78 million consumers annually. It’s an incredible amount of energy flowing invisibly into our homes every day.

What most homeowners don’t realize is their responsibility begins at the gas meter. While the utility maintains the lines up to the meter, you are responsible for all the piping on your side. These customer-owned “houselines” that feed your appliances require proper installation, inspection, and prompt repair.

Safety is paramount with natural gas. Unlike a water leak, a compromised gas line poses an immediate risk of fire, explosion, or carbon monoxide exposure. Because natural gas is odorless, utilities add a distinct “rotten egg” smell to help detect leaks. This is why professional installation and repair isn’t just a recommendation—it’s essential for your safety.

I’m Chris Kirsten from Professional Plumbing IE Inc., and I’ve spent years helping Inland Empire homeowners safely manage their natural gas systems. In this guide, I’ll explain how these systems work, when to call a professional, and what to expect from a proper installation or repair.

The Vast US Natural Gas Pipeline Network Explained

The primary function of the U.S. natural gas pipeline network is to transport gas from production points to consumers. This vital energy artery delivered an astonishing 29.2 trillion cubic feet (Tcf) of natural gas to approximately 78.3 million consumers in 2022 alone. Nearly 80 million homes and businesses rely on this unseen network daily.

The system’s scale is immense, with about 3 million miles of pipelines—enough to circle the Earth over 120 times. This feat of engineering ensures that communities like ours in Riverside, Eastvale, Corona, Norco, Jurupa Valley, and Mira Loma have reliable energy. For those interested, the U.S. Energy Information Administration (EIA) provides detailed data via its U.S. Energy Atlas, and the National Pipeline Mapping System offers a visual map.

From Wellhead to Your Meter: The Three Main Pipeline Types

The journey of natural gas involves a carefully orchestrated system of pipes designed for specific transport stages.

First, gathering pipelines collect raw natural gas from wellheads. These small-diameter lines bring gas to natural gas processing plants, where impurities are removed to meet quality standards.

Next, the purified gas enters transmission pipelines. These are the superhighways of the network—wide-diameter, high-pressure lines that transport gas across the country. Compressor stations are placed along these lines to maintain pressure and ensure continuous flow over thousands of miles.

Finally, the gas transitions into distribution pipelines as it approaches local communities. These smaller, lower-pressure lines run beneath our streets. From these, individual service lines connect to your property’s gas meter, bringing the gas safely to your home.

The Evolution and Growth of the Gas Network

The natural gas network we rely on today has a long history. Much of the mainline transmission and local distribution infrastructure was installed during a boom in the 1950s and 1960s. While robust, this aging infrastructure requires ongoing modernization to ensure safety and efficiency.

In recent years, technological breakthroughs like hydraulic fracturing (fracking) have dramatically increased U.S. natural gas production, particularly from shale formations. This “shale gas boom” has generally led to lower natural gas prices, fueling greater demand in electricity generation, industrial processes, and for export as liquefied natural gas (LNG).

This dynamic interplay of production, transportation, and demand shapes the availability and cost of natural gas for us here in the Inland Empire. The continued expansion of the distribution network is driven by the need to serve new commercial facilities and housing developments in our growing communities.

Understanding Your Natural Gas Line: Components and Types

Once natural gas passes through your meter, the system becomes your responsibility. This “houseline” is a critical network of pipes delivering gas to every gas-powered appliance in your home. A typical residential system includes:

- Gas Meter & Main Shutoff Valve: Where gas enters your property and can be shut off for the entire home.

- Houseline Piping: The network of pipes running through your home.

- Branch Lines & Appliance Shutoff Valves: Smaller pipes that split off to individual appliances, each with its own shutoff valve for isolation.

- Appliance Connectors: Flexible lines connecting the shutoff valve to the appliance.

- Drip Legs (Sediment Traps): Small pipe sections that collect debris before it enters and damages an appliance.

The materials used for these houselines are crucial for safety. In our service areas of Riverside and Corona, we primarily see two main types of piping.

Black Iron vs. CSST: Choosing the Right Pipe

The choice of material for interior piping is paramount for safety. We generally work with two main types: black iron pipe and Corrugated Stainless Steel Tubing (CSST).

Black Iron Pipe

This is the traditional, rigid, heavy-duty steel pipe used for decades. It’s incredibly durable but requires precise cutting, threading, and sealing, making installation labor-intensive. Over time, it can corrode in moist environments.

Corrugated Stainless Steel Tubing (CSST)

CSST is a modern, flexible alternative with a plastic coating. Its flexibility allows it to be routed through walls and ceilings with fewer fittings, speeding up installation. However, it requires specific bonding and grounding per the National Fuel Gas Code to protect against electrical surges.

Here’s a quick comparison:

| Feature | Black Iron Pipe | Corrugated Stainless Steel Tubing (CSST) |

|---|---|---|

| Durability | Very high; rigid and heat-resistant | High; flexible and corrosion-resistant |

| Flexibility | None; rigid, requires many fittings | High; can bend and snake through structures |

| Cost | Material cost typically lower, labor higher | Material cost typically higher, labor lower |

| Installation Speed | Slower; requires cutting, threading, many joints | Faster; fewer joints, easier routing |

| Primary Use | Traditional, often for main runs or exposed areas | Modern, for interior runs, appliance connections |

| Safety Note | Requires proper sealing, susceptible to corrosion | Requires proper bonding and grounding |

The choice depends on the application and local codes. We ensure any material we install is approved and installed to the highest safety standards, never using prohibited materials like plastic, copper, or galvanized pipe.

Fittings, Valves, and Safety Components

A safe gas system relies on essential fittings and valves.

- Shutoff Valves: These are the most critical safety components. A main shutoff is near your meter, and individual appliance shutoff valves are required near each gas appliance. Knowing how to locate and shut off your natural gas line is crucial for every homeowner.

- Drip Legs (Sediment Traps): These vertical pipes collect dirt, debris, or moisture from the gas flow, protecting sensitive appliance components. They are necessary for furnaces and water heaters.

- Regulators: While the utility installs the main regulator, some systems may require additional regulators to ensure appliances receive gas at the correct pressure.

- Flexible Appliance Connectors: These stainless steel lines connect the shutoff valve to the appliance, allowing for easier movement. They must be an approved type.

- Caps and Plugs: Any unused gas outlets must be securely capped to prevent leaks.

All components must be installed to code to ensure the integrity and safety of your natural gas system.

Professional Gas Line Installation and Repair

When it comes to your natural gas line, “DIY” is a word for danger. Any work involving gas lines—new installations, repairs, or adjustments—is not a job for the untrained. The risks of improper work are severe, including gas leaks, fires, explosions, and carbon monoxide poisoning.

Professional service is absolutely crucial. In California, and specifically in our service areas of Riverside, Eastvale, and Corona, we operate under some of the nation’s strictest gas line codes. These regulations exist to protect you and our community.

A licensed company like Professional Plumbing IE Inc. understands these complex codes and has the specialized tools and training to perform gas line work safely and compliantly. Attempting it yourself risks your family’s safety, voids insurance policies, and can lead to costly code violation repairs. When it comes to gas, safety is priceless.

Key Steps in a Professional Natural Gas Line Installation

We follow a meticulous process for every natural gas line installation to ensure safety and code compliance.

- Site Evaluation and Planning: We assess your property and design a custom plan, determining the safest and most efficient route for the new gas line.

- Material Selection and Sizing: We choose the appropriate piping material (black iron or CSST) and calculate the correct pipe diameter based on your appliances’ BTU needs and the length of the run to ensure proper pressure.

- Safe Routing and Trenching: For outdoor lines, we trench to the correct depth, always calling 811 before digging to locate existing utility lines. Indoor lines are routed securely with minimal structural impact.

- Proper Connections and Safety Features: Every connection is perfectly sealed. We also install all required safety components, such as shutoff valves and drip legs.

- Pressure Testing: This is a non-negotiable step. We pressurize the new line with air and monitor it to confirm there are absolutely no leaks before introducing gas.

- Final Inspection and Permitting: We handle all necessary permits, and the installation undergoes a final inspection by local authorities to ensure full compliance with all safety regulations.

Each step is executed with precision, guaranteeing a reliable and secure natural gas supply for your home.

Signs You Need a Natural Gas Line Repair

Recognizing the warning signs of a gas leak is paramount for your safety. If you notice any of the following, act immediately and call a professional.

- “Rotten Egg” Smell: The most common sign. Utility companies add a sulfur-like odorant called mercaptan to the naturally odorless gas to make leaks detectable.

- Hissing Sounds: A hissing sound near a gas line or appliance could indicate escaping gas.

- Dead or Discolored Vegetation: An underground leak can kill grass and plants above the line. You might also see bubbles in standing water.

- Unexplained High Gas Bills: A sudden spike in your gas bill without increased usage could signal a slow leak.

- Appliance Malfunctions: A pilot light that won’t stay lit or a sputtering burner can be related to a gas line issue.

- Physical Symptoms: In the event of a significant leak, you might experience dizziness, headaches, or nausea. Evacuate immediately if this occurs.

What to Do If You Suspect a Leak:

- Evacuate Immediately: Get everyone out of the house.

- Do NOT Cause a Spark: Don’t use lights, phones, or any electronics. Don’t start your car.

- Shut Off Gas (If Safe): If you can safely access your main gas shutoff valve outside, turn it off.

- Call for Help from a Safe Location: Once away from the house, call SoCalGas at 1-800-427-2200 and 911 if there’s immediate danger. For more details, see our guide on what to do if you suspect a gas leak.

Never try to find or fix a gas leak yourself. Always trust the experts.

Frequently Asked Questions about Natural Gas Lines

We understand homeowners have many questions about their natural gas line systems. Here are answers to some of the most common inquiries we receive in the Inland Empire.

How often should a natural gas line be inspected?

While there is no strict mandate for residential houselines, we strongly recommend a periodic inspection by a qualified professional every 3-5 years. Think of it as preventative maintenance.

Regular inspections can catch early signs of corrosion, wear, or minor leaks before they become dangerous. A professional will check all connections, valves, and pipe integrity using specialized leak-detection equipment. If you have older black iron pipes, routine checks are even more critical as their sealants can deteriorate. If you ever notice signs of a problem like a faint gas smell or appliance issues, call for an inspection immediately.

Can I install my own natural gas line for a new appliance?

No. Installing or modifying a natural gas line is absolutely not a do-it-yourself (DIY) project. The risks of fire, explosion, and serious injury are far too high.

- Safety Risks: Improper connections or testing can lead directly to dangerous gas leaks.

- Code Violations: Gas line work is governed by strict local and state codes and requires permits. DIY work is illegal and will not pass inspection.

- Insurance Issues: Your homeowner’s insurance will likely not cover damage caused by unpermitted or improperly installed gas lines.

Always hire a licensed professional for any work involving natural gas. Our team at Professional Plumbing IE Inc. is trained and certified to perform these installations safely and compliantly. You can learn more about our natural gas services on our website.

What is the average cost of a natural gas line installation?

The cost of a natural gas line installation varies significantly based on the project’s specifics. National averages, which often range from $250 to over $800, are only rough estimates. The actual cost for your home in Riverside, Corona, or a neighboring city will depend on several key factors:

- Pipe Length and Routing: Longer runs and complex routes (e.g., under a driveway or through finished walls) increase labor and material costs.

- Material Type: Black iron and CSST have different material and labor costs.

- Project Complexity: Connecting a single BBQ is much cheaper than re-piping an entire home or running a line to a new structure.

- Permit and Inspection Fees: These are required for all gas work and are part of the project cost.

- Condition of Existing Lines: If old pipes need to be replaced to meet current codes, the cost will increase.

For an accurate estimate custom to your specific needs, we always recommend a professional consultation. This allows us to provide a transparent, detailed quote.

Conclusion: Trust the Experts with Your Gas Line Needs

The natural gas line is an indispensable part of modern comfort, but it comes with a profound responsibility for safety. From the vast national network to the pipes inside your walls, this complex system demands professional expertise.

The safety of your home and family hinges on the proper installation, maintenance, and repair of your gas lines—especially the customer-owned piping on your side of the meter.

At Professional Plumbing IE Inc., we’ve served the Riverside, Eastvale, Corona, Norco, Jurupa Valley, and Mira Loma communities for nearly 40 years. Our family-owned business is built on a reputation for professional, guaranteed quality service. Our highly trained team prioritizes your safety and satisfaction above all else.

Never compromise on safety with DIY gas work. For reliable and safe gas line installation and repair services in the Riverside, CA area, contact our experienced team today. We’re here to ensure your gas supply is always secure and efficient.