Gas Distribution Pipe: 3 Critical Stages

The Hidden Network Beneath Our Streets

A gas distribution pipe is the network of underground pipes that delivers natural gas from large transmission lines to individual homes and businesses, operating at low pressure and typically made from steel or polyethylene materials. These pipes form the final link in a complex infrastructure that brings natural gas from wellheads to your water heater, furnace, and stove.

Key Components of Gas Distribution Systems:

- Distribution Mains – Pipes running under streets (2-24 inches diameter, 1/4-200 psi)

- Service Lines – Smaller pipes connecting the main to your meter (1/2-1 1/2 inches)

- Pressure Regulators – Devices that reduce gas pressure for safe home use

- Gas Meters – Equipment measuring your consumption at the property line

Every day in the United States, several billion cubic feet of natural gas travel through more than 2.2 million miles of distribution pipes to reach approximately 68 million residential customers and five million commercial customers. This vast network operates quietly beneath our feet, delivering the energy that heats our homes, cooks our food, and powers countless businesses.

Yet most people never think about this infrastructure until something goes wrong. Understanding how gas distribution pipes work isn’t just interesting—it’s essential for safety and making informed decisions about your home’s gas systems.

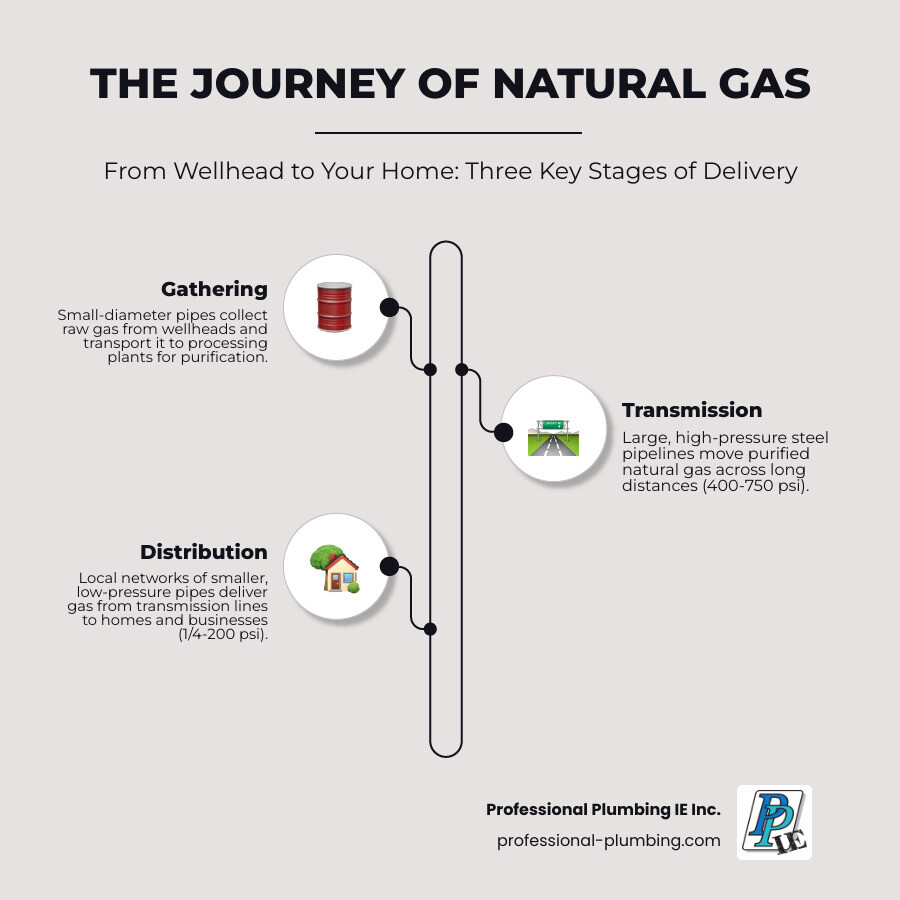

The journey of natural gas involves three stages: gathering systems collect raw gas, transmission pipelines transport it long distances, and distribution networks deliver it locally. Local Distribution Companies (LDCs) manage this final step, ensuring safe delivery to your home by maintaining pipes, reducing pressure, and adding the familiar “rotten egg” safety odor.

From Wellhead to Water Heater: The Journey of Natural Gas

The delivery of natural gas is a three-stage journey from a distant wellhead to your home’s water heater or stove. Each stage uses a different type of pipeline to move the gas safely and efficiently.

1. Gathering Systems: The journey begins at the wellhead, where raw natural gas is extracted. A network of small-diameter gathering lines collects this gas from multiple wells and transports it to processing plants. There, impurities like water and sulfur are removed to create “pipeline-quality” dry natural gas.

2. Transmission Systems: Once processed, the gas enters the transmission system—the interstate highway for energy. These are massive steel pipelines, typically 20 to 42 inches in diameter, that move enormous volumes of gas across states at high pressure. To overcome friction, compressor stations are placed every 50 to 60 miles to boost the pressure and keep the gas flowing. The U.S. has an impressive natural gas pipeline network of approximately 305,000 miles of these transmission lines.

3. Distribution Systems: The final handoff occurs at the citygate, where gas moves from high-pressure transmission lines to the local network managed by a Local Distribution Company (LDC). In communities like Riverside, Corona, and Jurupa Valley, the LDC takes over. At the citygate, pressure is dramatically reduced, and an odorant called mercaptan is added, giving gas its signature “rotten egg” smell for safety. The gas then enters the gas distribution pipe network—the smaller, lower-pressure pipes running under your streets that deliver gas directly to your property.

A sustainable alternative, Renewable Natural Gas (RNG), can also enter this system. Derived from organic waste from landfills or farms, RNG is chemically identical to conventional natural gas and can be injected into the same gas distribution pipe networks, seamlessly reaching your home.

The Role of Local Distribution Companies (LDCs)

Your LDC is the entity responsible for the final, critical stage of gas delivery in areas like Eastvale, Mira Loma, and Norco. Their key functions include:

- Managing the Local Network: LDCs own and maintain the vast web of gas distribution pipe under local streets and the service lines connecting to your home. This involves regular inspections, repairs, and replacements.

- Reducing Pressure: They safely reduce gas pressure from high transmission levels (over 1,000 psi) down to the low pressure needed for household appliances (as low as 1/4 psi).

- Ensuring Safety: LDCs add the mercaptan odorant at the citygate and constantly monitor the system for safety.

- Billing and Customer Service: The LDC is your point of contact for gas service. While some states allow you to buy the gas commodity from a third-party supplier, the LDC always handles the physical delivery through its pipes.

- Adhering to Regulation: LDCs are regulated by state public utility commissions, which oversee supply, pricing, and safety standards to ensure reliable and safe service. For a deeper dive into how this works, see this natural gas pipeline primer.

The Heart of the System: A Closer Look at Gas Distribution Pipe

The gas distribution pipe carrying gas the final miles to your home is the backbone of the local network. The materials used for these pipes have evolved significantly, from early cast iron and steel to the advanced plastics that dominate new installations today. This evolution is driven by a constant pursuit of safety, reliability, and longevity.

Choosing the Right Gas Distribution Pipe: Materials and Properties

The choice of pipe material is critical for the safety and durability of a gas network. Here’s a look at the common materials and their properties:

- Steel Pipes: Incredibly strong and able to handle high pressures, steel has been a workhorse for gas lines. However, it is heavy, costly to install, and susceptible to corrosion unless coated or protected. You’ll still find it in industrial settings and as black iron pipe for interior gas lines, though it also faces corrosion challenges.

- Galvanized Steel: This is steel with a protective zinc coating. While it resists rust better, the zinc can flake off and cause blockages, so it is generally not recommended for new gas installations.

- Polyvinyl Chloride (PVC): Common in plumbing and drainage, PVC is not used for natural gas distribution in the U.S. because it is too brittle to handle the pressures and temperatures safely.

- Medium-Density Polyethylene (MDPE): Introduced in the 1960s, this flexible, corrosion-resistant plastic became a new standard for gas distribution, offering major advantages over metal.

- High-Density Polyethylene (HDPE): Today’s gold standard, particularly PE4710 resin, has revolutionized gas networks. It offers superior strength, flexibility, and an expected lifespan of over 100 years.

The Rise of HDPE: Benefits in Modern Gas Distribution

Nearly all new and replacement gas distribution pipe installations use HDPE due to its significant advantages for safety, reliability, and cost-effectiveness.

- Leak-Free Joints: HDPE pipes are joined using heat fusion techniques like butt fusion or electrofusion. This process melts the plastic together, creating a seamless joint that is as strong as the pipe itself and won’t leak. At Professional Plumbing IE Inc., we use specialized electrofusion machines and butt fusion machines to ensure perfect connections.

- Corrosion Resistance: HDPE is immune to rust and corrosion from soil and moisture, which translates to a longer service life and lower maintenance costs compared to metal pipes.

- Flexibility: The pipe’s flexibility allows crews to bend it around obstacles and use trenchless installation methods. In earthquake-prone areas like Southern California, this flexibility allows the pipe to move with the ground rather than crack.

- Durability and Longevity: Studies show HDPE pipes have a service life of 100 years or more. The material is highly resistant to cracks, ensuring long-term reliability. You can find more details on HDPE pipe benefits in this resource.

- Lighter Weight: HDPE is much lighter than steel, making it safer for crews to handle and faster to install. It can also be supplied in long coils, reducing the number of joints needed in the field.

Anatomy of the Local Distribution Network

Once natural gas enters your community, a local network of pipes brings it to your home in Corona or business in Mira Loma. This system is composed of several key components that work together to ensure safe and reliable delivery.

Key Components and Their Functions

- Distribution Mains: These are the primary pipes, typically 2 to 24 inches in diameter, running under streets. They operate at pressures from 1/4 psi to 200 psi and are often laid out in grid patterns, allowing gas to be rerouted during maintenance without service interruptions.

- Service Lines: Smaller pipes (1/2 to 1 1/2 inches) branch off the main to connect to individual properties, ending at the gas meter.

- Pressure Regulator: This critical safety device is located at the meter and reduces the gas pressure to a safe level for your home’s appliances.

- Gas Meter: Positioned on the side of your house, the meter measures your gas consumption. Modern electronic meters can transmit readings automatically to the utility.

- Shutoff Valves: Located throughout the network and at each meter, these valves allow the gas flow to be stopped for emergencies or repairs. Every homeowner should know how to locate and shut off your natural gas line.

Nationally, installing a new gas line averages around $20 per linear foot, with total costs typically ranging from $265 to $850, though complex jobs can exceed $1,000.

Common Problems with Your Home’s Gas Distribution Pipe

Even durable gas distribution pipes can develop issues over time. Recognizing the signs of a problem is key to your family’s safety.

- Gas Leaks: This is the most serious concern. If you notice a “rotten egg” smell, hear a hissing sound, or see bubbling in wet ground or dead vegetation near a gas line, evacuate the area immediately and call for help from a safe distance. Our guide explains what to do if you suspect a gas leak. For local emergencies, we are ready to respond to a gas leak in Riverside.

- Improper Connections: Loose or poorly sealed fittings are a common source of leaks. This is why gas line work must be performed by qualified professionals.

- Corrosion and Rust: Older metal pipes can corrode and weaken over time, leading to leaks. Regular inspections can catch this before it becomes dangerous.

- Appliance Issues: Yellow flames (instead of blue), soot, or poor performance from gas appliances can signal a problem with your gas supply.

Your local utility is responsible for the pipes up to and including your meter. As the homeowner, you are responsible for all piping from the meter to your appliances. For any concerns, from installation to leak detection, contact us for professional natural gas services.

Safety First: Regulations and Best Practices

When it comes to gas distribution pipe networks, safety is the absolute priority. The industry operates under a strict framework of regulations and best practices to ensure the safe delivery of natural gas.

At the federal level, the Pipeline and Hazardous Materials Safety Administration (PHMSA) sets comprehensive safety standards for pipeline design, construction, and maintenance. State agencies add another layer of oversight, often with requirements custom to local conditions. Key safety measures include:

- Adding mercaptan to give gas its “rotten egg” smell for easy leak detection.

- Sophisticated leak detection programs and regular patrols by utilities.

- 24/7 emergency response teams ready to act immediately.

- Strict operator qualification standards and training for all pipeline workers.

- Rigorous pipeline testing before any new or repaired pipe is put into service, with polyethylene pipes adhering to the ASTM D2513 standard.

You can learn more about these fundamentals from the Office of Pipeline Safety.

Call 811: The Most Important Rule

Here’s a safety rule that could save your life: Call 811 before you dig. It’s simple, free, and it’s the law.

Accidental strikes from digging are a leading cause of pipeline incidents. Whether you’re planting a tree, installing a fence, or starting any project that breaks ground, you must call or click before you dig. Contacting 811 a few business days in advance notifies utilities to send technicians to mark the approximate location of buried lines, including gas distribution pipe. Always wait for the marks and dig carefully around them to prevent a dangerous accident.

Beyond digging safely, every homeowner should also know how to locate and shut off your natural gas line in an emergency.

Federal and State Oversight

The multi-layered system ensures pipeline safety. PHMSA serves as the primary federal regulator, enforcing safety rules for a pipeline’s entire lifecycle. At the state level, public utility commissions implement these standards locally, with the authority to inspect LDC operations, review safety plans, and mandate improvements.

The industry also contributes through technical standards from organizations like ASTM International. For example, polyethylene pipes must meet ASTM D2513, which defines material composition, physical properties, and testing procedures. This combination of federal, state, and industry oversight creates a robust safety net that protects communities across the country.

Frequently Asked Questions about Gas Pipes

You’ve made it this far, which means you’re serious about understanding the natural gas infrastructure that serves your home. That’s great! We get a lot of questions from homeowners in Riverside, Corona, and surrounding areas about their gas pipes. Here are the most common ones, answered in plain English.

What is the difference between a transmission and a distribution pipe?

Think of transmission pipes as the “interstate highways” of the gas network and distribution pipes as the “local streets.”

Transmission pipes are large-diameter (20-42 inches) steel pipelines that move massive volumes of gas at high pressure over long distances between regions.

Distribution pipes, on the other hand, are the local delivery system. Managed by your local utility, gas distribution pipe networks take gas from the “citygate” and deliver it to individual homes and businesses. Mains under the street are typically 2-24 inches, while the service line to your house is much smaller.

What are most modern gas distribution pipes made of?

Modern gas distribution pipe is overwhelmingly made from advanced plastics. The two main materials are medium-density polyethylene (MDPE) and high-density polyethylene (HDPE).

HDPE is now the gold standard for new and replacement lines. It’s flexible, immune to corrosion, and can be joined with leak-free fusion techniques. Unlike older metal pipes, HDPE has a service life of 100 years or more, making it a safer and more durable choice.

Who is responsible for the gas pipe connected to my house?

This is a critical question, as it determines responsibility for repairs.

Here’s the general rule: your local utility company (LDC) owns and maintains the distribution main running under the street, plus the service line that runs from that main to your property. They’re also responsible for your gas meter. Everything up to and including the meter outlet is on them.

But here’s where your responsibility kicks in: you own all the gas piping from the meter to your appliances. That includes the pipes running through your walls, the connections to your furnace, water heater, stove, and any other gas appliances. You’re responsible for keeping these lines safe, leak-free, and up to code.

This is why it’s so important to work with qualified professionals like us at Professional Plumbing IE Inc. for any work on your home’s gas lines. Whether you need a new line installed for an outdoor kitchen, suspect a leak, or want an inspection for peace of mind, having an experienced plumber handle your gas distribution pipe work isn’t just smart—it’s essential for your family’s safety.

Your Trusted Partner for Gas Line Safety

The natural gas distribution system is a complex network designed for safety and reliability. Understanding its key components, from the materials used in gas distribution pipe to the safety rules like calling 811, helps you make informed decisions and keep your family safe.

For the gas distribution pipe inside your home—from the meter to your appliances—proper installation and maintenance are essential. Natural gas is safe and efficient, but it demands professional expertise.

At Professional Plumbing IE Inc., we’ve spent nearly 40 years earning the trust of families throughout Eastvale, Riverside, Corona, Norco, Jurupa Valley, and Mira Loma. As a family-owned business, we understand that your home’s safety is your top priority—because it’s ours too. Our highly trained technicians bring decades of combined experience to every job, whether it’s installing a new gas line for your outdoor kitchen, detecting a suspected leak, or ensuring your existing system meets current safety standards.

We believe in doing the job right the first time, backing our work with guaranteed quality service at rates that respect your budget. Your satisfaction isn’t just our goal—it’s how we’ve built our reputation over four decades.

If you have any concerns about your home’s gas lines, or you’re planning an upgrade or new installation, don’t take chances. Natural gas service requires the expertise of qualified professionals who understand both the technology and the critical safety requirements.

Contact us for professional natural gas services today! We’re here to help keep your home safe, comfortable, and efficiently powered.

Pingback: Gas pipeline for house: Conquer 2026 Dealbreaker Fears

[…] gas distribution pipe […]