Natural Gas Pipe Installation Cost: Your Ultimate 2025 Guide

Understanding Natural Gas Pipe Installation Costs: What You Need to Know

Natural gas pipe installation cost varies widely based on your project’s scope, but knowing the numbers upfront helps you budget and plan. Here’s what homeowners across the U.S. are paying:

| Cost Type | Amount |

|---|---|

| National Average | $598 |

| Typical Range | $271 to $935 |

| California Range | $500 to $2,000+ |

| Per Linear Foot | $12 to $25 |

| New Line from Street | $2,000+ |

| Extending from Meter | $500 to $2,000 |

| Extending Existing Line | $360 to $740 |

If you’re planning to add a gas line for a new appliance, convert your home to natural gas, or extend your existing system, you’re probably wondering what it will actually cost. The answer depends on several factors: how far the pipe needs to run, what material you choose, the terrain you’re working with, and whether you’re connecting to the street or just extending from your meter.

In California, prices tend to run higher than the national average—sometimes significantly—due to stricter building codes, higher labor rates, and the complexity of working in developed areas. A simple 20-foot run to a new stove might cost $400 to $600, while a full installation from the street to multiple appliances could easily exceed $5,000.

The bottom line: Natural gas pipe installation is not a DIY project. It requires licensed professionals, permits, inspections, and strict adherence to safety codes. Get it wrong, and you’re looking at gas leaks, fire hazards, or worse.

I’m Chris Kirsten, and I’ve spent years helping Riverside homeowners steer the complexities of natural gas pipe installation cost through our family-owned plumbing company. Understanding these costs upfront means fewer surprises and better decisions for your home’s safety and efficiency.

Understanding the Natural Gas Pipe Installation Cost Breakdown

When it comes to installing a new natural gas line or extending an existing one, the total investment is more than just the pipe itself. It’s a blend of materials, labor, permits, and the unique challenges of your property. We’ve seen projects in Riverside, Eastvale, Corona, Norco, Jurupa Valley, and Mira Loma range from a few hundred dollars for a minor extension to several thousands for a comprehensive new installation from the street. Our goal is to explain these costs so you can plan your project with confidence.

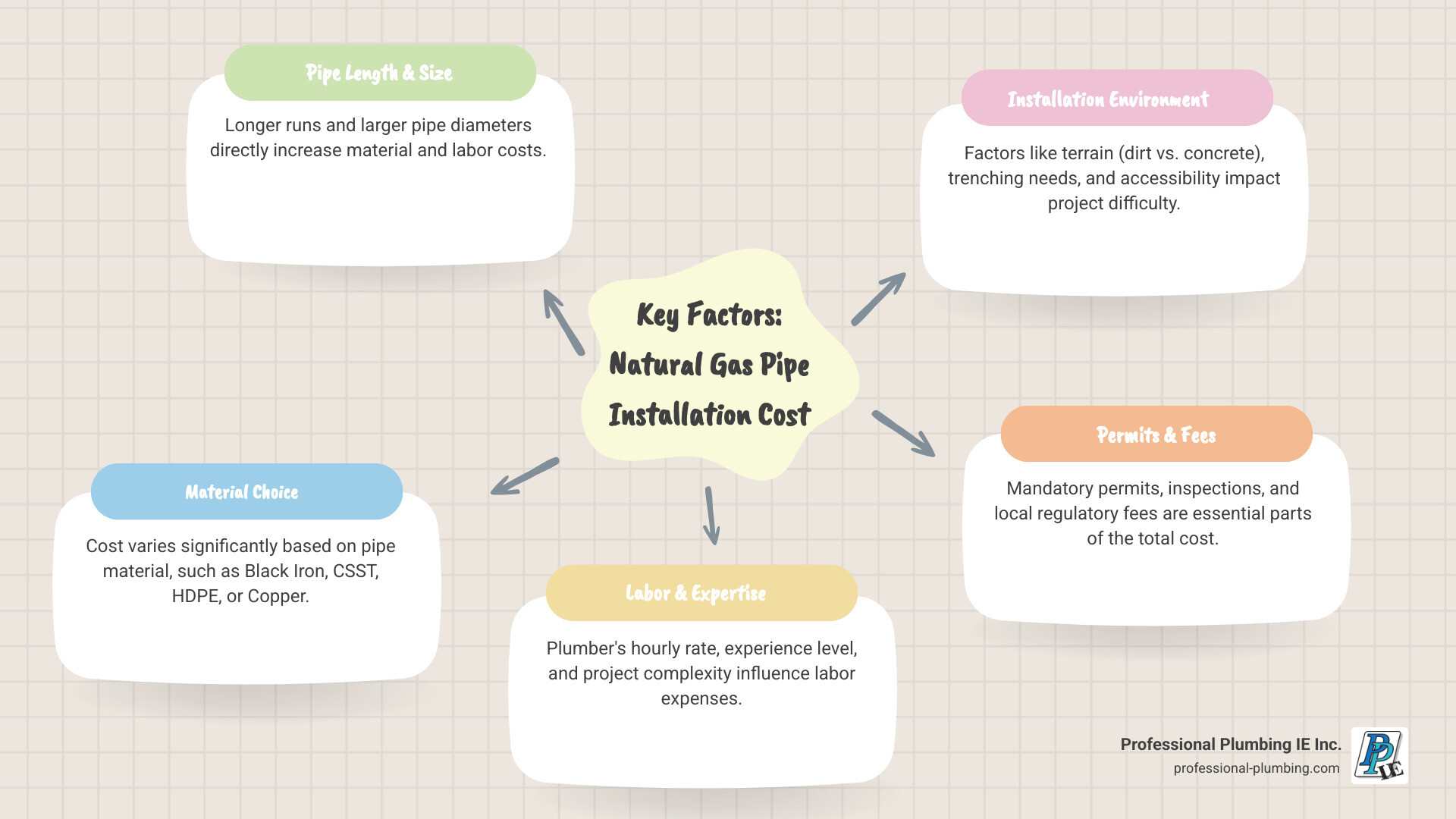

Key Factors Influencing the Natural Gas Pipe Installation Cost

Several variables come into play when calculating the natural gas pipe installation cost. Understanding these can help you anticipate expenses and make informed decisions.

- Pipe Length: This is often the most straightforward factor. Most gas line installations are priced per linear foot, typically ranging from $12 to $25. Naturally, a longer run from your main gas meter to a new appliance means more material and labor, increasing the overall cost. For instance, running a gas line for a new appliance is largely based on the length of the gas line and how easy it is to access the area.

- Pipe Diameter: Not all gas lines are created equal. The size of the pipe (its diameter) is determined by the BTU (British Thermal Unit) rating of the appliances it will serve. High-demand appliances like a furnace or a large tankless water heater require larger diameter pipes to ensure adequate gas flow. Larger pipes mean more material cost and can sometimes be more complex to install, driving up the price.

- Number and Type of Appliances: Each gas appliance you add or upgrade will need a dedicated gas line connection and potentially a shut-off valve. If you’re planning to hook up multiple appliances—say, a new stove, dryer, and water heater—you’ll need a system designed to handle the cumulative BTU load. This might require a larger main line and more branching within your home, adding to the complexity and cost.

- Location and Terrain: This is where things get interesting, especially in our diverse Southern California terrain.

- Dirt vs. Concrete/Asphalt: Installing a gas line in soft dirt is significantly less expensive than trenching through concrete driveways, asphalt patios, or even rocky soil. Trenching in dirt can cost $5 to $12 per linear foot, but if we need to cut through concrete or asphalt, prepare for additional costs for removal, disposal, and repair of these surfaces. Complicated underground installations can sometimes reach as high as $75 per foot.

- Above Ground vs. Underground: While most main gas lines are buried for safety and aesthetic reasons, interior lines might run through walls, attics, or crawl spaces. Each scenario presents its own challenges and labor requirements.

- Installation Method:

- Trenching: This is the traditional method, involving digging a trench to lay the pipe. It’s usually the most cost-effective for straightforward runs in accessible soil. However, if your yard has extensive landscaping or mature trees, we might need to factor in landscaping restoration costs.

- Directional Boring: For situations where trenching isn’t feasible or desirable—like under a driveway, sidewalk, or established garden—directional boring (also known as trenchless installation) can be used. This method drills horizontally underground, minimizing surface disruption. While it saves your landscaping, it’s a specialized technique that adds equipment and labor costs, making it more expensive than simple trenching.

For more detailed information on expanding your gas system, check out our guide on adding a gas line.

Pipe Materials and Their Impact on Price

The type of pipe material used for your natural gas line plays a significant role in the overall natural gas pipe installation cost, affecting both the material price and sometimes the labor involved. Local codes in places like Riverside, Eastvale, and Corona often dictate which materials are permissible for specific applications.

Here’s a comparison of common gas pipe materials:

| Material Type | Material Cost (per linear foot) | Durability | Flexibility | Common Uses & Notes |

|---|---|---|---|---|

| Black Iron | $4.90 – $9.00 | High | Low | Very durable, high heat resistance. Ideal for natural gas and propane. Often used for main lines and exposed piping. Requires threading and specialized tools for installation. |

| CSST (Corrugated Stainless Steel Tubing) | $2.00 – $4.00 | High | Very High | Flexible, lightweight, and easy to install, making it a popular choice for interior runs, especially in tight spaces. Generally more expensive than black iron per foot, but quicker installation can offset labor costs. |

| HDPE (High-Density Polyethylene) | $1.00 – $2.00 | High | High | Flexible, lightweight, corrosion-resistant. Excellent for underground use. Must be about 2.5 times thicker than PVC to handle similar pressure. |

| Copper | $1.00 – $3.00 | Medium | Medium | Corrosion-resistant, but generally not permitted for natural gas lines in many areas due to its softness and potential for improper soldering. Primarily used for propane in some regions, but check local codes carefully. |

| Galvanized Steel | $2.20 – $9.30 | High | Low | Often found in older homes (pre-1970s). Less common for new natural gas installations today due to potential for internal corrosion over time. |

| PVC (Polyvinyl Chloride) | $0.20 – $2.00 | Medium | Low | Very affordable and easy to install, but not universally approved for natural gas. If allowed, it’s typically for low-pressure applications. Always confirm with local codes. |

While some materials like PVC or HDPE might have a lower material cost, their suitability depends heavily on local regulations and the specific application (e.g., underground vs. above ground, low pressure vs. high pressure). For instance, in earthquake-prone California, flexible options like CSST are often preferred for appliance connections.

We’re always happy to discuss the best and most compliant materials for your project. If you’re curious about plumbing supplies in general, contact us.

Labor, Permits, and Other Additional Fees

Beyond pipe and trenching, a significant portion of your natural gas pipe installation cost comes from the skilled professionals performing the work and the necessary regulatory steps.

- Professional Expertise (Labor Costs): Installing gas lines is a job for licensed professionals—no ifs, ands, or buts. This isn’t just about knowing how to connect pipes; it’s about understanding gas pressure, flow rates, safety protocols, and local building codes. Plumber hourly rates for gas line installations or repairs typically range from $45 to $150 per hour. However, this can vary based on experience:

- Apprentice Plumber: $45 – $90 per hour

- Journeyperson Plumber: $60 – $110 per hour

- Master Plumber: $80 – $200 per hour

Given the critical safety aspect of gas work, we always recommend hiring a master plumber or a highly experienced journeyperson specializing in gas lines. You can find more detailed wage statistics from the US Bureau of Labor Statistics.

- Permit Costs: Almost every gas line installation, extension, or major repair requires a permit—either a building permit or a plumbing permit. These permits ensure that the work is inspected and meets strict safety codes. Permit fees typically range from $100 to $300, but can vary by municipality in our service areas. Your licensed contractor should handle the permitting process for you.

- Inspection Fees: After installation and before the gas line is activated, a mandatory inspection by local authorities is required. This ensures the work was done correctly and safely. Inspection fees usually fall between $50 and $75, though they can be up to $300 in some regions. Annual gas system inspections are also recommended, costing around $100 to $150.

- Gas Meter Installation: If you’re bringing natural gas to your property for the first time, you’ll need a gas meter. While the utility company typically owns and maintains the meter, there can be installation costs. A new residential gas meter installation generally costs between $300 and $600, including labor. In many cases, the utility company might cover some or all of this if you’re a new customer.

- Shut-off Valves: Safety is paramount, and individual shut-off valves for each appliance are crucial. These allow you to isolate the gas supply to a single appliance without shutting down your entire home’s gas. Installation costs for a standard shut-off valve can be $50 to $140 per appliance. In earthquake-prone areas like California, earthquake-sensitive shut-off valves are often required, adding $100 to $300 per valve (plus installation labor of $100 to $300). These automatically shut off the gas during seismic activity, a vital safety feature for our communities in Riverside, Jurupa Valley, and beyond.

Comparing Installation Scenarios and Related Services

The scope of your natural gas project significantly impacts the overall natural gas pipe installation cost. Whether it’s a new construction, a home remodel, or simply upgrading an appliance, each scenario presents unique challenges and price points.

New Line from the Street vs. Extending an Existing Line

This is often the biggest cost differentiator for homeowners in our service areas.

- New Line from the Street (Connecting to the Main): If your property doesn’t currently have natural gas service, or if the existing service needs a complete overhaul, you’re looking at a new line from the street to your house. This can be the most expensive option, often costing $2,000 or more. The good news is that utility companies often cover some or all of the cost for the main line installation up to your property line, and sometimes even the meter itself. The typical gas main installation costs around $200 to $300, but the longer the run from the main to your house, the more complex and costly it becomes for the homeowner’s portion. We always advise checking with your local gas provider about their specific policies on free or low-cost main gas line installations.

- Extending from the Meter: If you already have a gas meter but need to run a new line to a different part of your home or property (e.g., to a new outdoor kitchen), the cost typically ranges from $500 to $2,000. This involves connecting to the existing meter and running the new pipe.

- Extending an Existing Pipe (from an existing connection): This is generally the least expensive option, costing between $360 and $740. It applies when you need to extend an existing internal gas line to a nearby new appliance, provided the existing line has sufficient capacity for the additional BTU load.

Utility company policies can vary, so it’s always wise to research your local provider’s terms for new service or extensions. To understand the natural gas infrastructure in your area, you can check for natural gas lines in your area.

Appliance-Specific Natural Gas Pipe Installation Cost

The natural gas pipe installation cost can vary significantly depending on the appliance you’re connecting. Each appliance has different BTU requirements and may be located in areas that are easier or harder to access.

Here’s a breakdown of average costs for various appliance hookups:

- Stoves/Kitchen Range: Running a gas line to a kitchen stove typically costs $300 to $800. This often involves around 30 linear feet of piping, averaging about $20 per linear foot. If you’re converting from electric to gas and an existing gas line is nearby and has capacity, it can be on the lower end.

- Dryers: A gas dryer is often more efficient than an electric one. The cost to run a gas line to a dryer usually ranges from $150 to $1,000, with an average around $350.

- Water Heaters & Furnaces: These essential home systems often share similar gas line requirements. Installing a new gas line to power a water heater and furnace can cost $350 to $600, provided they are relatively close to the main gas supply.

- Fireplaces: Converting to a gas fireplace or installing a new one is a popular choice for ambiance and warmth. The gas line itself might cost $15 to $25 per linear foot, but the total installation for a gas fireplace (including the unit and venting) can range from $2,300 to $4,000.

- Outdoor Grills & Fire Pits: Extending your living space outdoors with a natural gas grill or fire pit is fantastic. Running a gas line for these can cost $20 to $25 per linear foot, with total project costs for just the line ranging from $200 to $700.

- Pool Heaters: Keep that pool warm! Adding a gas line to a pool heater typically costs $700 to $1,400. Pool heaters are high-BTU appliances, often requiring larger diameter lines.

- Generator Hookups: For peace of mind during power outages, a natural gas generator is a great option. Installing a gas line for a generator usually costs around $20 to $25 per linear foot, similar to other outdoor appliances, but the overall generator installation costs (including the unit) are much higher.

Gas Line Repair, Replacement, and Moving Costs

Sometimes, it’s not about new installations but dealing with existing infrastructure. Gas line repairs, replacements, or rerouting are critical for safety and can also incur significant costs.

- Leak Detection and Repair: Gas leaks are serious business. If you suspect a leak (rotten egg smell, hissing sound, dying vegetation near an underground line), immediately evacuate and call your gas company. Once the source is confirmed, professional repair is needed. Minor leaks, like those at a junction behind a stove, might cost $120 to $250. Hidden leaks in walls or crawl spaces are more complex to locate and repair, ranging from $270 to $760. The most expensive are buried line leaks, which can cost $1,500 to $5,000 due to excavation and subsequent landscaping repairs. Overall, gas line repairs typically cost $6 to $7 per linear foot or $75 to $150 per hour. If you ever suspect a gas leak, please refer to our guide on what to do if you suspect a leak.

- Moving a Line: During a remodel or renovation, you might need to move an existing gas line. The average cost to move or reroute a gas line is $15 to $25 per linear foot, depending on accessibility and complexity.

- Full Replacement: For older, corroded, or frequently leaking gas lines, a full replacement might be the safest and most cost-effective long-term solution. The typical gas line replacement cost is $8 per linear foot, with a minimum around $300 and an average of $700 for a single section. Replacing gas pipes throughout an entire home can range from $3,000 to $7,000.

- Capping a Line: If you’re removing a gas appliance and won’t be replacing it, the gas line needs to be safely capped. This prevents leaks and is a relatively inexpensive service, typically costing $50 to $200 for a callout, or $25 to $90 per cap if multiple lines are being sealed.

Safety, Savings, and Hiring a Professional

When it comes to natural gas, safety is not just a priority—it’s the priority. This is why we can’t stress enough the importance of professional installation.

Why Professional Installation is Non-Negotiable

Trying to cut corners with a DIY gas line installation is like playing with fire, except the stakes are much, much higher. The risks include:

- Explosions and Fires: Improper connections, incorrect pipe sizing, or inadequate testing can lead to dangerous gas leaks, which can ignite and cause catastrophic damage, injury, or even death.

- Code Violations: Gas line installations are governed by strict local, state, and national building codes. Non-compliant work can result in fines, forced removal and reinstallation, and difficulties selling your home.

- Insurance Issues: Homeowner’s insurance policies may be voided if damage or injury occurs due to unpermitted or improperly installed gas lines.

- Health Hazards: Even small, undetected gas leaks can lead to carbon monoxide poisoning, causing dizziness, nausea, confusion, and in severe cases, death.

Professional installation is non-negotiable for your safety and peace of mind. Our licensed plumbers are trained in all safety standards and adhere to all local codes, including California’s strict gas line codes, which are particularly stringent due to seismic activity.

From obtaining permits to performing comprehensive leak testing and ensuring proper pipe sizing, we handle every step with precision. While the entire process, from permits to connection, can take six to twelve weeks, the actual installation of the line might take a few days to a few weeks. The peace of mind knowing your home in Riverside, Eastvale, or Jurupa Valley is safe and compliant is truly priceless. You can learn more about our commitment to your home’s safety by exploring our residential services.

How to Save Money on Your Installation

While safety should always come first, there are smart ways to manage your natural gas pipe installation cost without compromising quality or safety:

- Get Multiple Quotes: Don’t settle for the first estimate. Contact at least three licensed professionals to compare pricing, scope of work, and proposed materials. This gives you a better understanding of fair market value for your project in our service areas.

- Bundle Services: If you’re planning other renovations or plumbing work, see if your plumber can bundle the gas line installation. Combining projects can often lead to savings on labor costs, as the crew is already on-site.

- Choose Cost-Effective Materials (Wisely): Discuss pipe material options with your plumber. While black iron is a robust choice, flexible CSST can be quicker to install in some interior situations, potentially saving on labor. HDPE is often a cost-effective option for underground runs. Always balance upfront cost with long-term durability and local code compliance.

- Plan Ahead: A well-planned project is a cost-efficient project. Determine the optimal route for your gas line, identify any potential obstacles (like trees or concrete), and obtain permits in advance. Rushed jobs or unexpected complications almost always increase costs.

- Check for Government Rebates and Energy Company Incentives: Some local governments or utility companies offer rebates or incentives for converting to natural gas, upgrading to high-efficiency gas appliances, or installing new gas lines. It’s worth checking with your local gas provider or municipal energy programs in Riverside, Corona, or Norco to see if any programs apply to your project.

Frequently Asked Questions about Gas Line Installation

We often get asked similar questions from homeowners in our service areas. Here are some of the most common ones:

Who installs gas lines?

Gas lines should always be installed by licensed professionals. This includes licensed plumbers, certified gas specialists, or technicians from your local utility company. For residential and commercial properties in Riverside, Eastvale, and surrounding communities, we, as a licensed plumbing company, have the expertise and certifications to handle all your natural gas line needs. The importance of credentials cannot be overstated; ensuring your installer is properly licensed and insured protects your home and family.

How deep are gas lines buried?

For safety, gas lines must be buried at a specific depth to protect them from accidental damage. The minimum depth for a residential gas line is typically 18 inches, with a preferred depth of 24 inches. However, local building codes in places like Jurupa Valley or Mira Loma can have variations, so we always verify the exact requirements for your specific property. And remember, before any digging project, always call 811 to have underground utilities marked! It’s free and prevents potentially dangerous and costly accidents.

Do I need a permit to run a gas line?

Yes, almost always! Running a new gas line, extending an existing one, or even making significant repairs typically requires either a plumbing permit or a building permit from your local municipality. These permits are crucial because they trigger mandatory inspections by local authorities, ensuring the work meets stringent safety codes. As part of our professional service, we handle the entire permitting process for your project, making sure everything is up to code and inspected properly.

Conclusion: Plan Your Project with Confidence

Understanding the natural gas pipe installation cost can seem daunting, but by breaking down the factors—from pipe length and material to labor and permits—you can approach your project with a clear budget and realistic expectations. While cost is a consideration, safety must always be the top priority.

For nearly 40 years, Professional Plumbing Inc. has been serving homeowners and businesses in Riverside, CA, and the surrounding communities, including Eastvale, Corona, Norco, Jurupa Valley, and Mira Loma. Our family-owned and operated business is built on a foundation of professional, guaranteed quality service at affordable rates, ensuring our customers’ satisfaction and, most importantly, their safety.

For expert advice and a transparent quote on your gas line project, contact our team of certified professionals. We’re here to help you power your home safely and efficiently. Contact us for natural gas services.