Plumbing Natural Gas Line: 5 Critical Safety Steps

Why Natural Gas Line Work Requires Professional Expertise

Working on plumbing natural gas line systems is one of the most critical—and dangerous—tasks in residential plumbing. Here’s what you need to know:

Key Facts About Natural Gas Line Plumbing:

- Professional Installation Required – Gas line work requires licensed plumbers due to explosion and fire risks.

- Common Materials – Black iron pipe, CSST (corrugated stainless steel tubing), copper, and PE pipe for underground.

- Permits Mandatory – All gas line installations require permits and inspections per the International Fuel Gas Code.

- Safety First – Gas leaks smell like rotten eggs, and any suspected leak requires immediate evacuation and a 911 call.

- Never DIY – Improper installation can void insurance, result in fines, and create life-threatening hazards.

Natural gas is an efficient energy source for about half of all U.S. homes, but the infrastructure that delivers it demands respect and expertise.

The bottom line: Gas line plumbing is not a DIY project. Period.

Unlike minor plumbing fixes, mistakes with gas lines can lead to explosions, fire, carbon monoxide poisoning, or death. A single improper connection can be catastrophic.

This guide explains how gas line systems work, what the installation process involves, and why you must always hire a licensed professional for any gas line work.

I’m Chris Kirsten with Professional Plumbing IE Inc. Our family-owned team has served Southern California for 40 years, handling complex plumbing natural gas line installations. We’ve seen the dangers of amateur work and are committed to educating homeowners on the importance of professional service.

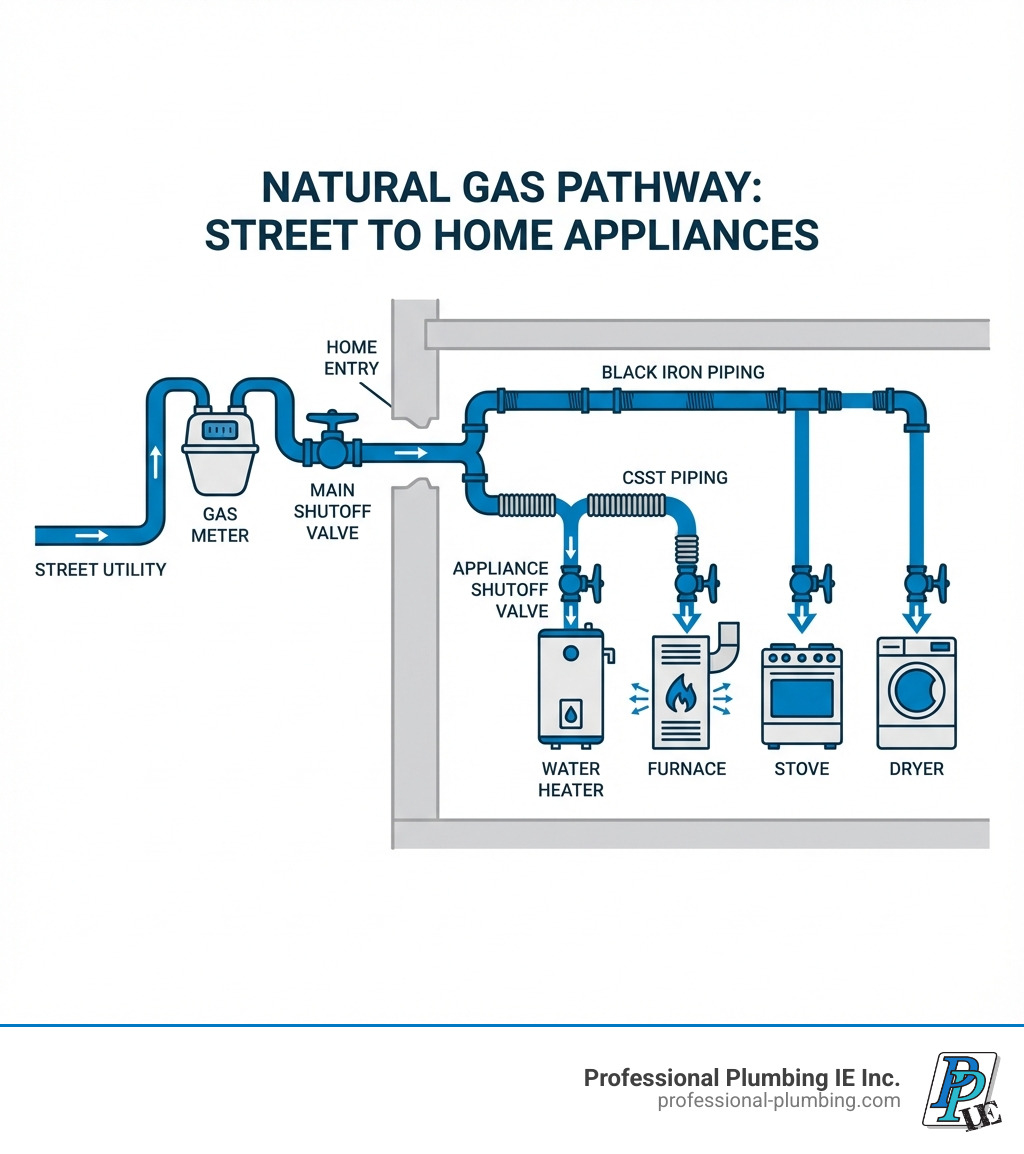

Understanding Your Home’s Gas Line System

Understanding your home’s plumbing natural gas line system is the first step in appreciating its complexity. This section covers the basic layout, materials, and how to identify key components.

How to Identify Existing Natural Gas Lines

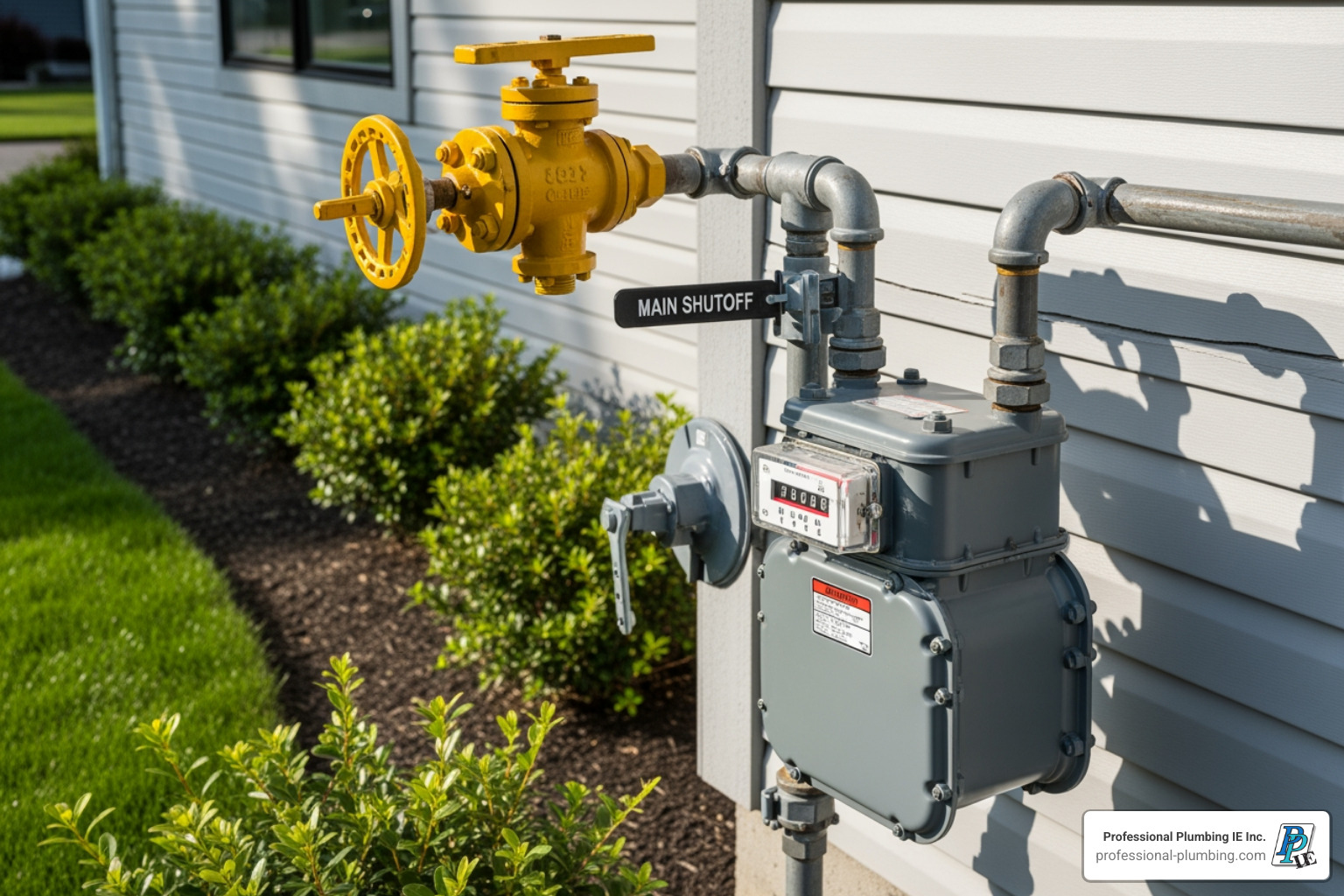

Your gas system starts at the meter, usually located outside your home. Next to it is the main gas shutoff valve, a critical component for emergencies. Know its location, but only turn it off if absolutely necessary. A professional must always be the one to turn it back on and relight any pilot lights.

From the meter, the gas line enters your home and branches out to appliances. You can trace these pipes through basements or crawl spaces. In areas like Riverside and Corona, you’ll typically see rigid, black iron pipes or flexible, yellow corrugated stainless steel tubing (CSST).

You’ll find connections to major appliances such as your:

- Stove/Oven

- Clothes Dryer (gas models)

- Water Heater

- Furnace/Boiler

- Fireplace

- Outdoor BBQ/Fire Pit

Each appliance also has its own smaller shutoff valve nearby for isolating it during service.

Common Materials for Plumbing Natural gas line

Choosing the right material for plumbing natural gas line systems is critical for safety and code compliance. Here’s a look at the most common materials used in homes across Eastvale, Norco, and Mira Loma:

| Material | Pros | Cons | Typical Use |

|---|---|---|---|

| Black Iron Pipe | Very durable, rigid, strong, traditional, fire-resistant. | Prone to corrosion if exposed to moisture, labor-intensive installation, requires threading. | Main distribution lines, risers, exposed runs in basements/utility rooms. |

| CSST (Corrugated Stainless Steel Tubing) | Flexible, easier/faster installation, fewer connections, good for seismic activity. | Requires proper bonding/grounding to prevent lightning damage, susceptible to puncture if not protected. | Branch lines, runs through walls/ceilings, connecting to appliances. |

| Copper Tubing | Corrosion-resistant, flexible, good heat transfer. | Not permitted for primary gas distribution in many areas (including ours), higher cost, easily damaged. | Short appliance connectors (code dependent), sometimes for propane. |

| Polyethylene (PE) Pipe | Flexible, corrosion-resistant, easy to install. | Underground use only, cannot be used inside structures, susceptible to UV degradation. | Underground service lines from meter to house, outdoor gas appliance runs. |

Black Iron Pipe: The traditional standard, black iron pipe is robust and reliable, especially for main lines. However, installation is labor-intensive, and it can rust if exposed to moisture.

CSST (Corrugated Stainless Steel Tubing): CSST is popular for its flexibility, which speeds up installation and reduces the need for fittings. It’s great for renovations but requires proper bonding and grounding to prevent lightning damage. You can find options like corrugated stainless steel tubing kits.

Copper Tubing: Common for water lines, copper’s use for natural gas is often restricted by local codes. Where allowed, it’s used for short appliance connectors but is more expensive and less durable than other options.

Polyethylene (PE) Pipe: This flexible plastic pipe is for underground use only, connecting the utility main to your meter or running to outdoor appliances. It’s corrosion-resistant but cannot be used inside or exposed to sunlight.

Material choice is dictated by safety standards and local codes. A licensed plumber will ensure the correct, compliant materials are used for your plumbing natural gas line project.

Safety First: Gas Line Codes, Leaks, and Precautions

Working with natural gas is extremely hazardous and not a DIY project. This section covers the critical safety measures, regulations, and leak detection steps to protect your home.

Recognizing and Responding to a Natural Gas Leak

Utility companies add a chemical called mercaptan to naturally odorless gas, giving it a distinct “rotten egg” smell as a primary warning sign of a leak.

Other indicators of a gas leak include:

- Hissing or whistling sounds from a pipe or appliance.

- Bubbling in standing water over an underground gas line.

- Dead or dying vegetation in a specific patch over an underground line.

- A white cloud or dust cloud near a gas line.

What to do if you suspect a natural gas leak:

- Evacuate immediately: Get everyone, including pets, out of the house.

- Don’t use electronics: Do not use light switches, cell phones, or anything that could create a spark.

- Don’t create sparks: Avoid turning appliances on or off, lighting matches, or using open flames.

- Call 911 from a safe distance: Once you are safely away from your home, call emergency services.

- Call your utility company: After contacting 911, notify your gas utility company.

Never try to find or fix a gas leak yourself. Leave it to the professionals.

Critical Safety Precautions for Gas Line Work

When a licensed professional from Professional Plumbing IE Inc. works on your plumbing natural gas line, they follow strict safety protocols to prevent accidents.

- Shut off gas supply: The first step is always to shut off the main gas supply at the meter.

- Ensure proper ventilation: Well-ventilated areas help dissipate any residual gas.

- No smoking, no open flames: Any source of ignition is a severe hazard.

- Prevent sparks: Tools that can create sparks are used with extreme caution or avoided.

- Use proper tools: Specialized, often non-sparking, tools are essential for gas line work.

- Personal Protective Equipment (PPE): Plumbers wear appropriate safety gear.

These precautions highlight why gas line work is not a DIY job; the risks are too high.

Local Codes and Permits for Natural Gas Work

Building codes for plumbing natural gas line work are rigorously enforced. The International Fuel Gas Code (IFGC) is the standard, but local jurisdictions like Riverside, Eastvale, and Jurupa Valley may have specific amendments.

Nearly all gas line work requires a permit from your local building department. This vital safety measure involves:

- Plan submission: Detailing the proposed work.

- Mandatory inspections: A certified inspector reviews the work at key stages.

- Pressure testing: The lines are pressurized with air to detect leaks before gas is introduced.

Attempting gas line work without permits is illegal and dangerous. You risk:

- Code violations and fines

- Invalidated homeowner’s insurance

- Difficulty selling your home

Our team at Professional Plumbing IE Inc. handles the entire permit and inspection process, ensuring your plumbing natural gas line project is compliant and safe across all our service areas.

Installing a Natural Gas Line: A Professional’s Overview

This overview of the professional plumbing natural gas line installation process highlights its complexity and the expertise required. It is not a DIY guide.

Essential Tools and Materials for the Job

A professional’s toolkit for gas line work is specialized. Critical tools and materials include:

- Pipe wrenches

- Pipe threader (for black iron pipe)

- Pipe cutter

- Thread sealant (pipe dope) designed for gas lines

- Gas leak detection solution

- CSST cutters and specialized fittings

- Manometer for pressure testing

- Pipe hangers and supports

This list shows the precision and knowledge required; using these tools correctly is vital for safety.

The Installation Process: From Planning to Testing

Gas line installation is a meticulous, multi-step process.

- Planning the Pipe Route: We map the safest, most efficient route, considering structural elements, utilities, and code-required clearances.

- Calculating Pipe Size: We calculate the required pipe diameter based on the total BTU load of all appliances, run length, and gas pressure. Incorrect sizing can cause appliance malfunction.

- Shutting Off the Gas: The main gas supply is shut off at the meter before work begins.

- Cutting and Threading Pipes: For black iron, pipes are cut to length and threaded to create secure connections.

- Applying Thread Sealant Correctly: Gas-specific thread sealant is applied to male threads to ensure a gas-tight seal without clogging the line.

- Assembling the Line: Pipes and fittings are assembled and secured with hangers to prevent movement. CSST requires specialized fittings.

- Connecting to the Appliance Shutoff Valve: The line terminates at an accessible shutoff valve for each appliance, allowing for isolated service.

- Performing a Pressure Test: A mandatory pressure test is performed. The line is filled with air and monitored with a manometer for any pressure drop, which indicates a leak. This is often witnessed by a city inspector.

- Performing a Leak Test (with gas): After the pressure test passes and gas is restored, every connection is checked with a leak detection solution. Any bubbles indicate a leak that must be fixed and retested.

This technical process requires years of training, which our licensed professionals in Riverside, CA, possess.

Why You Should Always Hire a Professional for Plumbing Natural Gas Line

The risks of improper gas line work are severe. This section explains why hiring a certified professional for any plumbing natural gas line task is a necessity for your safety and peace of mind.

The Dangers of DIY Gas Line Installation

While DIY projects can be rewarding, gas line work is too dangerous to attempt yourself. The risks are life-threatening:

- Risk of Explosion: An undetected leak can fill your home with gas. A single spark from a light switch or static electricity can cause a catastrophic explosion.

- Fire Hazards: Even a small, continuous gas leak can fuel a fire if it’s near an ignition source.

- Carbon Monoxide Poisoning: Improperly installed gas appliances can produce deadly, odorless carbon monoxide (CO). Poor ventilation allows CO to fill your home, with symptoms often mistaken for the flu.

- Invalidated Homeowner’s Insurance: Your homeowner’s insurance will likely deny claims for damage caused by unpermitted or amateur gas work, leaving you liable for all costs.

- Code Violations and Fines: DIY gas work without permits leads to heavy fines from local authorities in Jurupa Valley and Norco, plus mandatory professional correction.

These are serious risks. We’ve seen the heartbreaking aftermath of amateur mistakes.

Benefits of a Licensed Gas Plumber

Hiring a licensed and insured gas plumber, like the experts at Professional Plumbing IE Inc., is an investment in safety and peace of mind. Here’s why:

- Proper Training and Certification: Our plumbers have extensive, specific training and hold all necessary state licenses and certifications.

- Knowledge of Local Codes: We are experts in the local codes for Riverside, Corona, and Eastvale, ensuring your project is compliant and passes inspection.

- Correct Tools and Materials: We use specialized tools and code-approved materials for a safe and efficient job.

- Liability Insurance: Our comprehensive liability insurance protects you and your property.

- Guaranteed Workmanship: We guarantee our work, performing installations and repairs to the highest standards for long-lasting safety.

- Peace of Mind: The greatest benefit is knowing your plumbing natural gas line system is safe, correct, and code-compliant, protecting your family and home.

Frequently Asked Questions about Natural Gas Lines

Here are answers to common questions we receive from homeowners about their plumbing natural gas line systems.

What’s the difference between natural gas and propane lines, and can they be interchanged?

Natural gas and propane are not interchangeable without professional modification. Here’s why:

- Gas Pressure: Natural gas is delivered at a much lower pressure than propane.

- Appliance Orifices: Appliances have orifices sized specifically for each gas type. Using the wrong one is dangerous and can cause appliance malfunction.

- Pipe Sizing: Pipe sizing requirements can differ between natural gas and propane to ensure adequate fuel supply.

- Conversion Kits: Switching an appliance between gas types requires a professional conversion kit installed by a qualified technician.

The bottom line: Never connect an appliance to the wrong gas type without professional conversion. It is extremely dangerous and can lead to fires, explosions, or carbon monoxide poisoning.

How much does it cost to install a new gas line?

The cost to install a new plumbing natural gas line varies based on several key factors:

- Pipe Length: Longer pipe runs increase material and labor costs.

- Material Type: Material costs differ. CSST may reduce labor time compared to black iron pipe.

- Job Complexity: Complex routes through finished walls or concrete are more expensive than simple runs in accessible areas like basements.

- Permit Fees: These are mandatory and vary by municipality (e.g., in Riverside or Corona).

- Labor Rates: Rates vary by market and the plumbing company’s experience.

- Appliance Connections: The number of appliances being connected affects the project scope.

Costs can range from a few hundred to several thousand dollars. For an accurate estimate for your project in Eastvale, Norco, or Mira Loma, contact a licensed professional for an on-site assessment.

Can I use flexible appliance connectors for a new line?

Flexible appliance connectors are only for the “last mile” connection between a gas appliance (like a stove or dryer) and its dedicated shutoff valve. They are not for running new gas lines through walls, floors, or ceilings.

Here’s what you need to know:

- Appliance Connectors vs. CSST: Do not confuse these connectors with CSST (Corrugated Stainless Steel Tubing). CSST is a robust, code-approved piping material for gas distribution; appliance connectors are not.

- Purpose: They provide a movable connection for easy appliance installation and maintenance.

- Restrictions: Codes prohibit running these connectors inside walls, ceilings, or floors. They must be accessible.

- Length Limits: Connectors are usually limited by code to 6 feet in length.

For running new gas lines, always use code-approved materials like black iron pipe or CSST, installed by a professional. If you’re looking for flexible gas line connectors, ensure they are used only for their intended purpose.

Conclusion: Trust the Experts with Your Natural Gas Lines

This guide has covered plumbing natural gas line systems, from identifying components to the importance of professional, safe installation. While natural gas is an efficient energy source, its delivery system demands expert handling.

The risks of DIY gas work—explosions, fires, carbon monoxide poisoning, and legal issues—are too high. Your family’s safety and your home’s integrity depend on the correct installation and maintenance of these vital systems.

At Professional Plumbing IE Inc., we empower homeowners with knowledge. For 40 years, our family-owned business has provided guaranteed, professional service across Eastvale, Riverside, Corona, Norco, Jurupa Valley, and Mira Loma, CA. Our trained team handles all your plumbing natural gas line needs safely, efficiently, and to code.

Don’t gamble with gas. For safe, reliable, and code-compliant work, trust the experts. Contact us for professional gas line installation and repair services today.