Commercial Kitchen Plumbing: Expert Guide 2025

Why Commercial Kitchen Plumbing is the Backbone of Your Food Service Business

Commercial kitchen plumbing is far more than just pipes and drains—it’s the operational backbone that determines whether your food service establishment can legally operate and serve customers safely. Unlike residential kitchens, commercial operations face high-volume water usage, strict health codes, mandatory grease management, and equipment that demands precise water temperatures and pressures.

Quick Answer: What You Need to Know About Commercial Kitchen Plumbing

- Essential Components: Hand sinks, three-compartment sinks, pre-rinse stations, floor drains, grease traps, and high-capacity water heaters.

- Key Requirements: Backflow prevention devices, proper drainage and venting, and specific water temperatures for handwashing (100°F+) and sanitizing (150°F+).

- Critical Compliance: Grease interceptors are mandatory in most jurisdictions, with significant fines for violations.

- Common Issues: Clogs from FOG (fats, oils, grease), low water pressure, leaks, and inadequate hot water supply.

Sanitation failures, often linked to inadequate plumbing, are a leading cause of food-related illnesses. Your plumbing isn’t just about convenience; it’s about safety, compliance, and keeping your business running without costly downtime. A single plumbing failure can shut down your entire operation, costing thousands in lost revenue.

Whether you’re planning a new commercial kitchen, upgrading an existing facility, or dealing with persistent plumbing issues, understanding these systems is essential for success.

Core Components and Design Principles

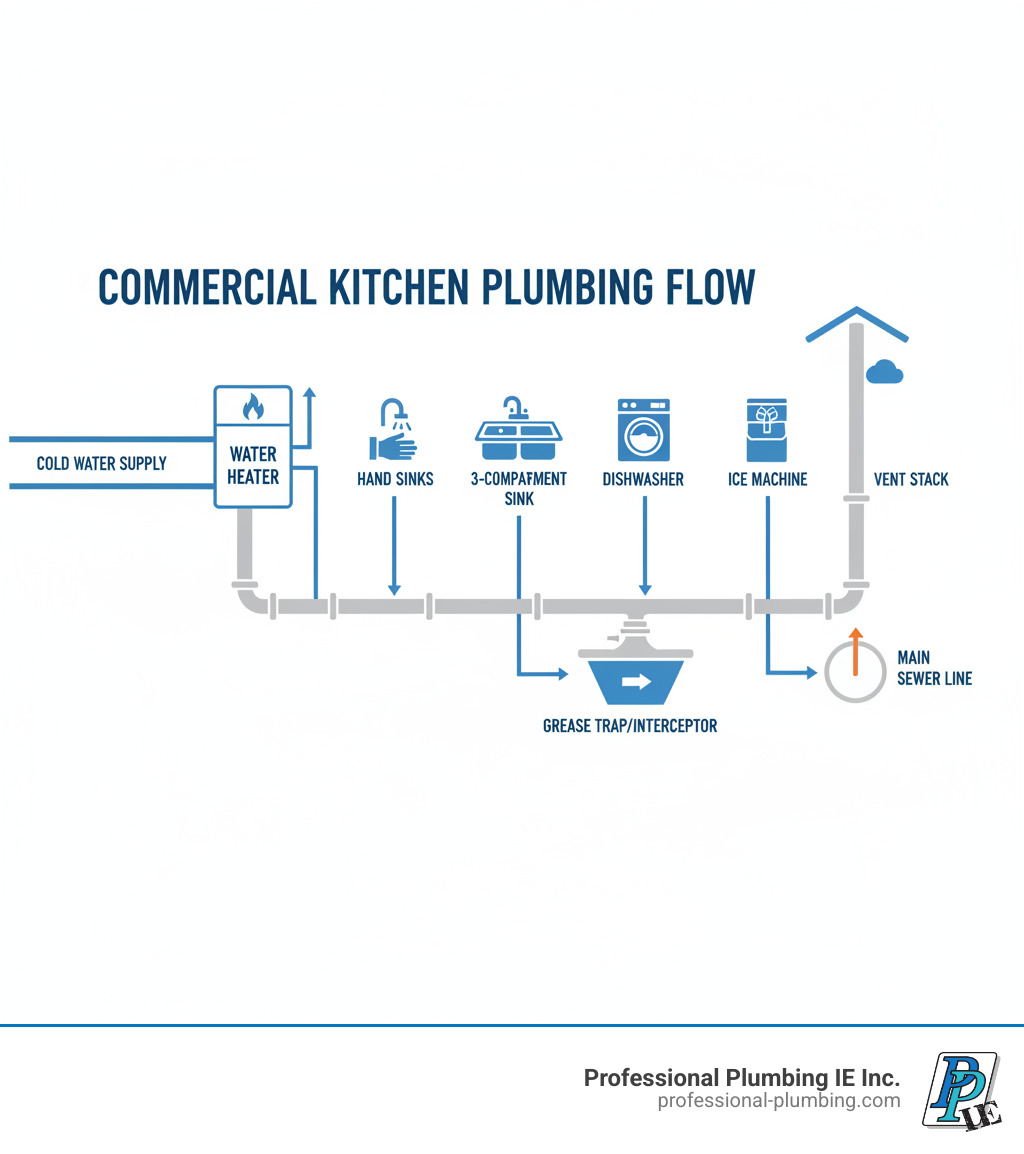

A well-designed commercial kitchen plumbing system is the circulatory system of your kitchen, working tirelessly to keep everything flowing smoothly. Success comes down to three core principles: a robust water supply, effective drainage, and the right heavy-duty fixtures. When designed well, your staff barely notices it; when it’s not, everything grinds to a halt.

We’ve spent nearly 40 years helping commercial kitchens get this right. More info about our Kitchen Plumbing services

Essential components for commercial kitchen plumbing

Health codes and high-volume use demand specialized fixtures, each serving a specific purpose:

- Sinks: Commercial kitchens require multiple sinks. Hand-washing stations are non-negotiable in prep areas. The three-compartment sink is the workhorse for washing, rinsing, and sanitizing. Prep sinks are for washing ingredients, and mop/utility sinks keep cleaning operations separate from food areas. A guide to food premises requirements highlights these specific needs.

- Pre-rinse units and Faucets: Powerful pre-rinse sprayers blast food debris off dishes before washing, increasing efficiency. Commercial faucets are built for constant use, often with hands-free controls like foot pedals or sensors.

- Floor Drains and Sinks: Floor drains are critical for catching spills and cleaning water, preventing slip hazards. Floor sinks are receptors for indirect waste lines from equipment like ice machines, using an air gap to prevent backflow contamination.

Water Supply, Heating, and Backflow Prevention

Commercial kitchens have an enormous demand for hot water. A restaurant dishwasher alone may need 140°F water for washing and 180°F for sanitizing. This requires high-capacity water heaters and often booster heaters for specific equipment. Sizing these units correctly is crucial; running out of hot water can shut down your kitchen.

Adequate water pressure is just as important for pre-rinse sprayers and dishwashers to function correctly. However, the most critical aspect is keeping the water supply clean. Backflow prevention devices are mandatory components that stop contaminated water from flowing backward into your clean water lines, a concept known as cross-connection control. This is essential for public health and required by code. More info about our Commercial Services

Drainage, Venting, and Equipment Integration

Getting wastewater out safely is the other half of the battle. Drainage pipes need the proper slope to flow effectively and must be made of durable, corrosion-resistant materials. Venting systems are equally vital, as they prevent sewer gases from entering the kitchen and allow wastewater to flow smoothly.

Many pieces of equipment, like ice machines and steamers, require indirect waste connections with air gaps—a physical space between the drain line and the floor drain—to prevent contamination. Integrating specialized equipment is key:

- Dishwashers need robust hot water lines and drainage connected to a grease trap.

- Ice machines require a potable water supply and an indirect drain.

- Steamers and combi ovens have specific water pressure and temperature needs.

- Gas-powered equipment requires professionally installed gas lines with correct sizing and shut-off valves.

Proper integration ensures your kitchen hums along without plumbing interruptions.

Residential vs. Commercial: Key Plumbing Differences

We often hear the question, “It’s just a kitchen, right? How different can the plumbing be?” The answer is: very different. A residential kitchen is like a sedan, while a commercial kitchen plumbing system is a heavy-duty truck, engineered for massive loads, constant use, and strict safety regulations.

Understanding these differences is crucial for any food service facility:

- Durability and Usage Volume: A home kitchen is used for a few hours daily; a commercial kitchen runs hard for 12+ hours. Fixtures and pipes must be built to handle relentless, high-volume use.

- Code Complexity: Commercial kitchens must comply with a maze of health, fire, building, and municipal codes that are far more stringent than residential rules.

- Pipe Diameter: Residential kitchens use smaller drain pipes (e.g., 1.5-inch). Commercial kitchens require larger 2-inch or greater pipes to handle the high volume of wastewater and food solids.

- Fixture Grade: Commercial fixtures are heavy-duty workhorses, typically stainless steel, built for performance and sanitation, not just aesthetics.

- Grease Management: This is a major distinction. Commercial kitchens are required by law to have grease traps or interceptors to capture fats, oils, and grease (FOG) before they enter the municipal sewer system.

- Water Temperature: Commercial kitchens need water at 100°F+ for handwashing and 150°F-180°F for sanitizing, requiring high-capacity water heaters and booster systems not found in homes.

TABLE comparing Residential vs. Commercial Kitchen Plumbing

| Feature | Residential Kitchen | Commercial Kitchen |

|---|---|---|

| Pipe Size | Smaller diameter (e.g., 1.5-inch drains) | Larger diameter (e.g., 2-inch+ drains) for higher volume |

| Fixture Type | Standard, often ceramic or lighter materials | Heavy-duty, stainless steel, built for resilience and hygiene |

| Grease Trap | Not typically required | Mandatory by code |

| Hot Water Needs | Moderate, standard water heater | High-capacity water heaters, often with booster heaters, specific temperature outputs |

| Regulations | General plumbing and building codes | Extensive health, building, fire, and municipal codes |

| Usage Volume | Intermittent, low volume | Continuous, high volume |

| Durability | Designed for typical home use | Engineered for constant, rigorous industrial use |

The bottom line is that commercial plumbing requires specialized knowledge. Treating it like a home project can lead to costly failures, health code violations, and business disruptions.

The Critical Role of Grease Traps and Interceptors

If one component defines commercial kitchen plumbing, it’s the grease trap or interceptor. Every time you cook, you create fats, oils, and grease (FOG). Without proper management, FOG becomes a ticking time bomb for your plumbing system.

Commercial kitchens generate massive amounts of FOG. As it cools in your pipes, it solidifies, creating blockages that can cause wastewater to back up into your kitchen. This leads to foul odors, health code violations, and potential shutdowns. Beyond your walls, FOG can block municipal sewer lines, causing environmental hazards and public health risks.

Grease traps and interceptors are the solution. They are a mandatory barrier, required by law in Riverside and surrounding areas, to capture FOG before it enters the sewer system. Ignoring these requirements can lead to severe penalties, including fines up to $100,000 in some jurisdictions, forced closures, and legal liability. What is grease?

Types, Sizing, and Maintenance

Grease traps are smaller, indoor units for lower-volume kitchens, while grease interceptors are larger, outdoor units for high-volume operations. Both work by slowing wastewater, allowing FOG to float to the top and solids to sink, while cleaner water flows out. They should be installed on any fixture discharging grease, including sinks, woks, and dishwashers.

Proper sizing is critical and requires professional assessment based on your kitchen’s wastewater volume and menu. An undersized trap will fail, while an oversized one is an unnecessary expense.

Once installed, maintenance is key:

- Scrape First: Train staff to scrape food scraps and grease into the trash before washing. This is the most effective daily practice.

- Inspect Regularly: Check the trap weekly or monthly to monitor FOG levels. The rule is to clean it before FOG and solids exceed 25% of the unit’s capacity.

- Schedule Professional Servicing: Most kitchens require professional cleaning at least monthly, with high-volume operations needing it more often. Licensed professionals use specialized equipment like hydro-jetters to thoroughly clean the trap and connecting lines, ensuring compliance and preventing emergencies.

Think of grease trap maintenance like changing the oil in your car—it’s a non-negotiable part of protecting your investment. We provide scheduled maintenance and detailed service records to prove your compliance with health inspectors.

Navigating Regulations for Commercial Kitchen Plumbing

Commercial kitchen plumbing is governed by a complex web of regulations designed to protect public health. Businesses in Eastvale, Riverside, and our other service areas must steer multiple layers of rules. We’ve spent nearly four decades helping owners meet these requirements, so you don’t have to become a code expert.

Your system must comply with health codes from agencies like the Riverside County Department of Environmental Health, which dictate sanitation standards, water temperatures, and backflow prevention. It must also adhere to the California Plumbing Code (CPC) for installation standards and local municipal by-laws, which often have specific rules for grease management and wastewater discharge. Any new installation or major modification requires permits and inspections before you can legally operate. We stay current on all national, state, and local codes to ensure your project passes inspection the first time, avoiding costly delays. View our past Commercial Projects

Common Issues in Commercial Kitchen Plumbing and Prevention

Even the best systems face challenges in a demanding kitchen environment. Most issues, however, are preventable.

- Clogs: The most common problem, caused by FOG and food debris. Prevention: Train staff to scrape plates thoroughly, use drain strainers, and never pour grease down a drain. Schedule regular professional hydro-jetting to clear buildup.

- Leaks: A dripping faucet or hidden pipe leak wastes money and can cause water damage and mold. Prevention: Conduct routine visual inspections and address any leak immediately, no matter how small.

- Low Water Pressure: This can slow down your entire operation and prevent equipment from cleaning properly. Prevention: A professional can diagnose the cause, which could be anything from clogged aerators to undersized pipes.

- Water Temperature Issues: Water that isn’t hot enough for handwashing or sanitizing is a serious health code violation. Prevention: Schedule regular maintenance for your water heaters and booster heaters to ensure they function correctly.

- Foul Odors: These usually signal sewer gas entering your kitchen from dry drain traps or clogged vents. Prevention: Regularly pour water down floor drains to keep traps full and have a professional address any venting problems.

The best strategy is combining staff training with professional oversight. Schedule comprehensive plumbing inspections at least once a year and ensure your team knows where main water and gas shut-off valves are located in an emergency.

Frequently Asked Questions about Commercial Kitchen Plumbing

Over our nearly 40 years in business, we’ve answered countless questions about commercial kitchen plumbing. Here are the most common ones.

How many sinks are required in a commercial kitchen?

At a minimum, you will need several dedicated sinks, each for a specific purpose required by health codes. The exact number depends on your operation, but typically includes:

- A dedicated hand-washing sink for every food prep area, complete with hot water (100°F+), soap, and paper towels.

- A three-compartment sink for the manual washing, rinsing, and sanitizing of dishes and utensils.

- A prep sink for washing raw ingredients.

- A mop or utility sink for cleaning activities, kept separate from food areas.

A guide to food premises requirements explains the importance of separating these functions. We work with local inspectors to ensure your kitchen has exactly what it needs to be compliant.

What are the water temperature requirements for sanitizing?

Water temperature is critical for safety and compliance. Health codes have strict requirements:

- Hand-washing: Water must be at least 100°F (38°C), and some local codes may require up to 110°F.

- Sanitizing: If using hot water to sanitize, the wash cycle often needs to be above 150°F (65°C). The final rinse in a commercial dishwasher must typically reach 180°F (82°C) to effectively kill bacteria.

Meeting these high temperatures requires commercial-grade, high-capacity water heaters and often booster heaters installed at the dishwasher. Running out of hot water can lead to a health department shutdown, so proper system design is essential.

How often should a grease trap be cleaned?

The general rule is to clean your grease trap before fats, oils, grease (FOG), and solids exceed 25% of its total capacity. For most commercial kitchens, this means professional cleaning is needed at least once a month.

However, high-volume restaurants, especially those with grease-heavy menus, may require cleaning every one to two weeks. A small café might only need quarterly service. Your local municipal by-laws will specify the maximum time allowed between cleanings, and health inspectors will check your maintenance logs. Neglecting this task leads to backups and hefty fines. We recommend a regular, professional maintenance schedule custom to your kitchen’s output to ensure you remain compliant and avoid costly emergencies.

Conclusion

Running a successful food service business is demanding. Your commercial kitchen plumbing shouldn’t be another source of stress. When designed, installed, and maintained by experts, your plumbing system works quietly in the background, ensuring system longevity, business continuity, and the safety and compliance that keep your doors open.

At Professional Plumbing IE Inc., we’ve spent nearly 40 years mastering what commercial kitchens in Riverside, Corona, Eastvale, and the surrounding areas need to thrive. As a family-owned company, we treat your business like our own. Our highly trained team understands the unique demands of your industry—from mandatory grease traps to 180°F sanitizing rinse temperatures.

Whether you need expert installation for a new restaurant, preventative maintenance for an existing facility, or urgent emergency repairs, we provide the experience you can trust. We don’t just fix problems; we prevent them.

Your kitchen is the heart of your business. Let us ensure the plumbing that powers it never misses a beat.

Contact us for expert plumbing services in Riverside and find why food service establishments across the Inland Empire rely on us for guaranteed quality service at affordable rates.